KLINGER MAXIFLEX Spiral Wound Gaskets

The Design Principle

Maxiflex spiral wound gasket shave the ability to recove runder the action off luctuating loads caused by process fluid pressureand temperaturechanges,flangefacetemperaturevariations,

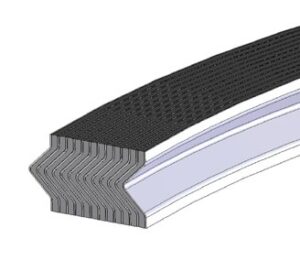

flange rotation,bolt stress relaxation and creep.The gasket sealing element consists of apre-formed metallic windings trip with layer so fas ofter,more compressible sealing material which,during compression,is densified and flows to fillim perfections in the flang esurfaces.The metals trip holdsthe filler giving the gasket mechanical resistance and resilience.Aboveisthe“Maxiflex”spiral wound gasket’s basic sealing element.Severallay ers of specially formed continuous V shaped (alsocalled chevr on shaped) metals trip sarespirally wound with alternate plies of so ftfiller strip.The V profile allows the gasket to actas a spring and the depthis carefully controlled to give the sealing element the best compression and recovery characteristics. Maxiflex spiral wound gaskets are manufactured to specifications of ASMEB16.20.

Computer controlled winding machines carefully monitor and adjust the tension of the windings trips. Auniform density through out the product is produced.This provides the spring-like action within the gasket that resists buckling and maintain saseal even when subject to fluctuating compressive loads.

Product Advantages:

Maxiflex spiral wound gaskets combine the ease of sealing a graphite,PTFE or micafiller with the strength afforded by aspecially profiled metallic,spring

-like reinforcement. These aling element is manufactured by interleaving plies of alternating metallic windings tripand filler to createa gasket that is robustand easy to install. Maxiflex spiral wound gasket screate a very tight and reliableseal suitable for high temperature and pressures

and can be manufactured to suit standard flanges and also custom-designed vessels. Maxiflex gaskets are capable of giving an excellent seal over a wide range of flange surface finishes, but as a general guide we suggest under general duties, a flange surface finish of 125-250μin. (3.2-6.3 μm).Above is the“Maxiflex”spiral wound gasket’s basic sealing element.Several layers of specially formed continuous V shaped (also called chevron shaped)metals trips are spirally wound with alternate plies of soft filler strip.

The V profile allows the gasket to act as aspring and the depthis carefully controlled to give the sealing element the best compression and recovery characteristics.Maxiflex spiral wound gaskets are manufactured to specification so fASMEB16.20.Computer controlled winding machines carefully monitor and adjust the tension of the windingstrips.Auniformdensitythroughouttheproductisproduced.Thisprovidesthespring-like action within the gasket that resists buckling and maintain saseal even when subject to fluctuating compressive loads.

Read More